In the heart of Piove di Sacco, Italy, a company with a vision beyond commercial success emerged in 1998. JVP, a manufacturer specializing in raised steel floors, set out not only to conquer the global market but to do so with products that embodied advanced technology, high performance, and environmental responsibility. As a testament to their commitment, JVP has always sought ways to improve their manufacturing processes by obtaining different environmental certificates. In this article, we delve into JVP’s story, exploring the challenges faced and the transformative impact of their decision to embrace cradle to cradle principles.

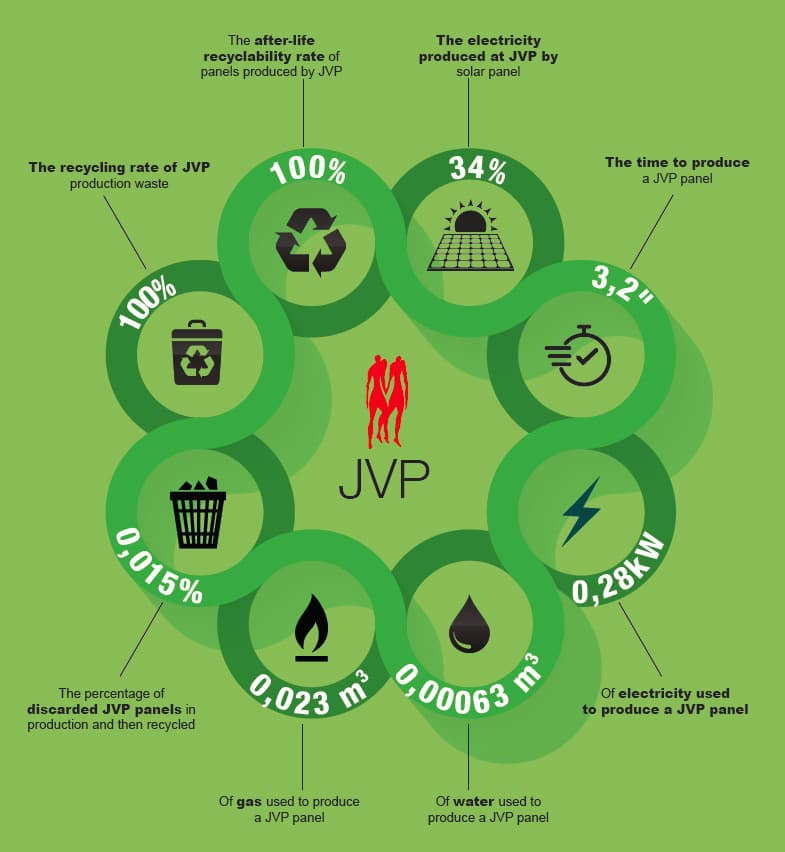

Founded by professionals well-versed in the raised technical flooring sector, JVP’s mission extended beyond business success from the very beginning. The company consciously adopted an environmentally friendly approach, aiming to reduce the environmental impact of its products throughout their lifecycle. From the selection of raw materials to production processes that minimize waste, installation methods, and a forward-thinking program for reuse and recycling, JVP embraced a circular economy approach. This ethical stance positioned them as pioneers in an industry where environmental considerations are increasingly becoming a priority.

Since their establishment, they have received several environmental certificates, and three years ago, they decided to obtain the Cradle to Cradle certificate. This decision was not without its challenges. “At that time, in Italy, the certificate was almost unknown, and we were looking for someone able to guide us through the study and application of the certification. We worked with a foreign partner since there were no consultants in Italy working on this specific certification,” Carlo Valerio, President of Confapi Padova and a key partner at JVP, explained. The decision not to give up was both an environmental and business decision. “The Cradle to Cradle certification process is a methodology for continuous improvement of environmental ecology, destined to represent a reference for numerous production chains. Among the advantages that the certificate can bring to the company is the reduction of risks, the increase of competitive advantage, and the reduction of production costs. Furthermore, it is strictly in line with the objectives defined by the European Agenda 2030, so much so that its future mandatory nature for certain production sectors is foreseeable,” Mr. Valerio emphasized the strategic advantages of adopting the cradle to cradle approach. The certification process demanded careful analysis of every aspect of production and distribution, a rigorous journey that some might view as daunting or expensive. However, JVP saw this as an opportunity. “Participating in high-profile projects for commercial brands across Europe and beyond is essential for those aiming at the forefront of industry innovation. Architects today are increasingly seeking solutions that go beyond conventional environmental standards. In this context, Cradle to Cradle certification stands out as the latest and potentially most significant frontier, thanks to its progressive approach.”

In a landscape where environmental responsibility is gaining precedence, such successful and sustainable business practices present an inspiration for others. JVP’s story exemplifies how sustainable practices, while demanding, are a crucial step towards not only meeting the evolving expectations of the market but also contributing to a healthier planet. Or in the words of Mr. Valerio: “Companies must work hard to get a certificate. They need to demonstrate that every single step of the production and distribution of their products is in accordance with cradle to cradle principles. It’s clear that it is not easy or cheap, but in the end, the transformation helps the environment. It is almost a gift because the transformation and certification are paid for by the companies, but the results are given to everybody.”

The interview was conducted by Padova Chamber of Commerce.